FV/MFV Series Flow Control Values

Enjoy Complete and Precise Flow Control!

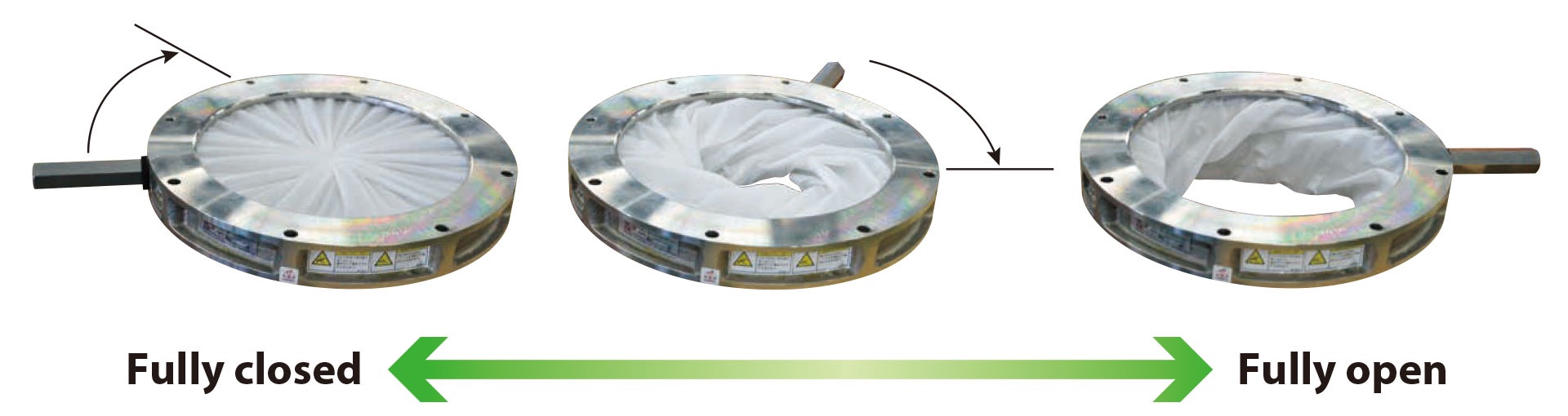

The FV and MFV Series control valves attach to the discharge openings of bins, hoppers or chutes to control the amount of material flowing through. Featuring a sleeve that opens and closes in a concentric circle like a camera aperture, these unique valves are perfect for distributing, mixing, sampling, bagging, and otherwise processing ultra-fine powders. The FV valves open and close manually with an easy-to-operate handle, while the MFV valves come equipped with a motor that will adjust the aperture with the flick of a switch. Both the FV and MFV valves are available in aluminum or stainless steel to suit the application.

Example of Application

FV Series manually operated flow control values

MFV Series motor-operated flow control values

FV Manually Operated Flow Control Value

Structure and Materials of Main Components

| Components | A Type (Aluminum) |

S Type (Stainless steel) |

|---|---|---|

| Housing | Aluminum | Stainless |

| Control ring | Brass | Stainless |

| Holding rings (large and small) |

Stainless | Stainless |

| Spiral stops (large and small) |

Stainless | Stainless |

| Spacer | Stainless | Stainless |

| Stud bolts | Carbon steel | Stainless |

| Handle | Resin | Stainless |

| Sleeve | Acrylic-coated nylon taffeta | |

Outer Dimensions

Dimension Table

Unit: mm

| Model | A | B | C | D | E | F | G | H | I | J | K | L | Weight (kg) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type A | Type S | |||||||||||||

| FV-4A (S) |

100 |

155 | 140 | 172 | 32 | 60 | 3-M6 |

3-φ7 |

60゚ | 11 | 10 | 11 | 1.2 | 2.2 |

| FV-6A (S) |

150 |

230 |

214 | 210 | 35 | 90 | 3-M8 | 3-φ9 | 60゚ | 11 | 12 | 12 | 2.5 | 4.4 |

| FV-8A (S) | 204 |

283 |

267 | 236 | 35 | 115 | 3-M8 | 3-φ9 | 60゚ | 11 | 12 | 12 | 3.5 | 5.5 |

| FV-10A (S) |

254 |

345 | 325 |

268 |

42 | 146 | 4-M10 | 4-φ11 | 45゚ | 15 |

12 |

15 | 5.0 | 9 |

| FV-12A (S) | 305 | 410 | 390 | 300 | 45 | 172 | 4-M10 | 4-φ11 | 45゚ | 16.5 |

12 |

16.5 | 8.0 | 13 |

The "A"and "S"at the end of the model numbers indicate aluminum and stainless steel, respectively.

The pressure exerted on the valve by the powdered material must be 0.014 MPa or less.

MFV Series Motor-operated Flow Control Value

Specifications

Standard Specifications

| Model | Power Source |

Reversible motor | Gear head |

Opening/closing time (sec) |

Gross weight (kg) |

Cable | ||

|---|---|---|---|---|---|---|---|---|

| Output(W) | Current(A) | 50Hz | 60Hz | |||||

| MFV-4A1/4S1 | 100V 50/60Hz |

25 | 0.6 | Speed reduction ratio 1:30 |

2.4 | 2.0 | 3.2 | VCT3-core 0.75mm2X1m |

| MFV-6A1/6S1 | 25 | 0.6 | 3.8 | 3.2 | 7.6 | |||

| MFV-8A1/8S1 | 25 | 0.6 | 4.8 | 4.0 | 8.6 | |||

| MFV-10A1/10S1 | 40 | 0.9 | 6.0 | 5.0 | 14 | |||

| MFV-12A1/12S1 | 40 | 0.9 | 7.2 | 6.0 | 18 | |||

The "A"and "S"at the end of the model numbers indicate aluminum and stainless steel, respectively.

MFV series are fully-closed and fully-open type only.

Outer Dimensions

Dimension Table

Unit: mm

| Model | A | B | C | D | E | F | G | H | J | K |

|---|---|---|---|---|---|---|---|---|---|---|

| MFV- 4A1 (S1) | 220 | 183 | 168 | 80 | 35.2 | 100 | 145 | 60 | 3-M6 | 3-φ7 |

| MFV- 6A1 (S1) | 250 | 245 | 171 | 115 | 38.2 |

150 |

214 | 60 | 3-M8 | 3-φ9 |

| MFV- 8A1 (S1) | 275 |

298 |

171 | 141.5 | 38.2 | 204 | 267 | 60 | 3-M8 | 3-φ9 |

| MFV-10A1 (S1) | 315 | 368 | 218 | 172.5 | 46.5 | 254 | 325 | 45 | 4-M10 | 4-φ11 |

| MFV-12A1 (S1) | 350 | 433 | 221 | 205 | 49.5 | 305 | 390 | 45 | 4-M10 | 4-φ11 |

Type A: Aluminum Type S:Stainless steel.

Please contact us if you need a custom-made product.

Standard painting color of SS parts except drive unit: Munsell 2.5G7/2.

Connection Diagram

Example of Application

Flow control

Attached to the outlet of a hopper, the flow rate is adjusted by "squeezing". Essential for mixing, blending, bagging, and other processes.

Easy adjustment from fully open to fully closed (FV type)

Valves for easily damaged materials (e.g. tablets)

For mixer input port